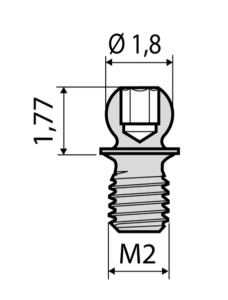

Ref. 039SFM2

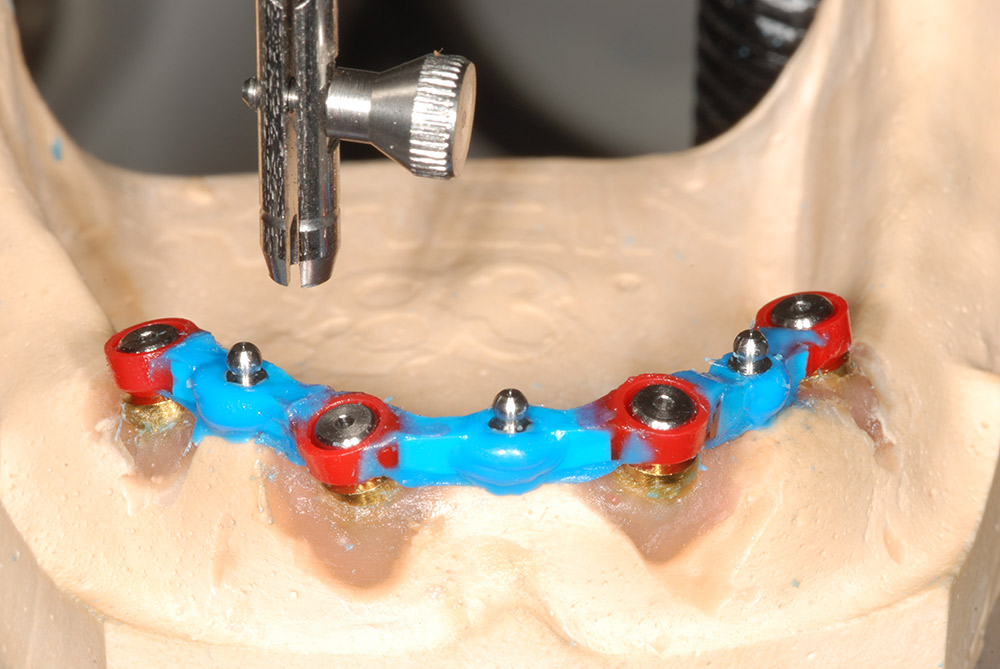

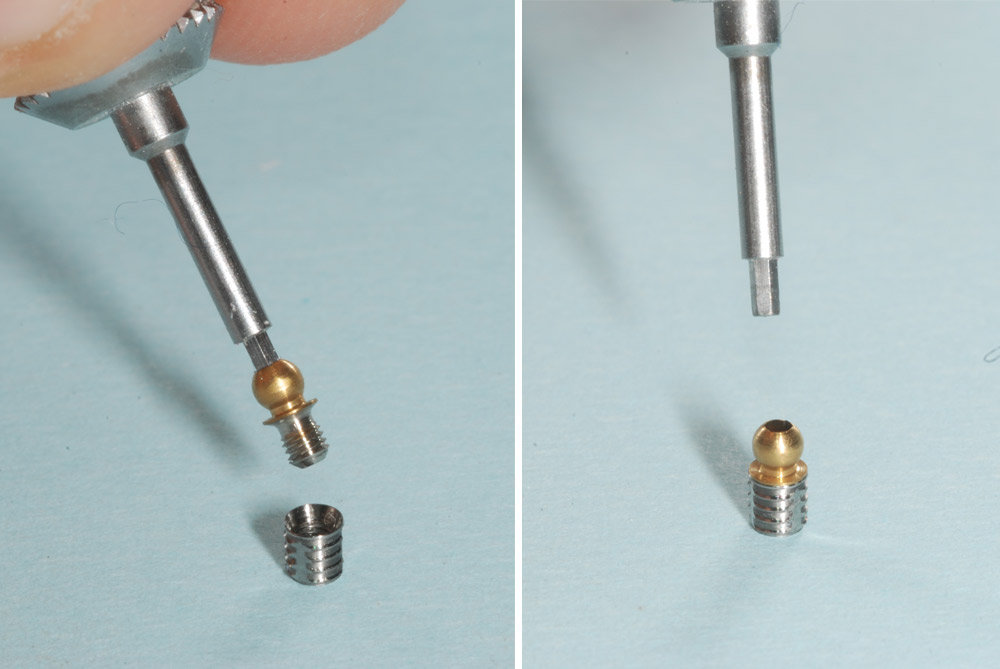

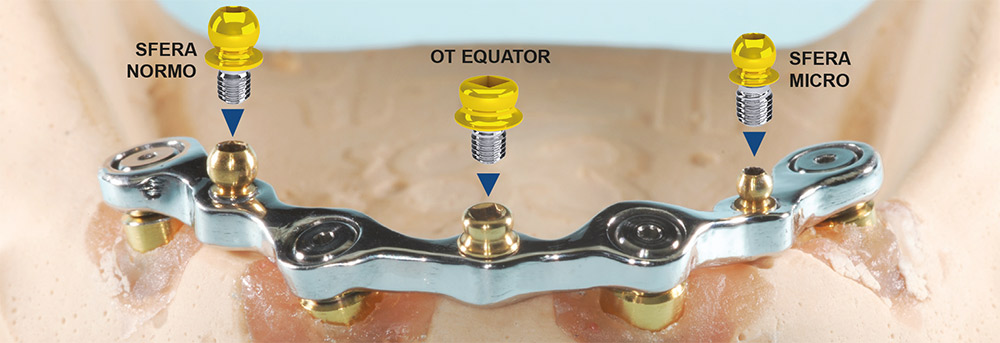

• 1 SINGLE THREADED SPHERE MICRO SIZE + TiN (hex 0.9mm, thread 2.0mm)

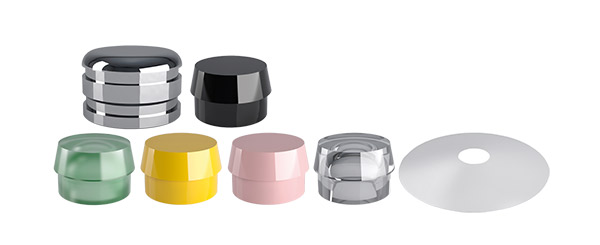

Ref. 192ACM

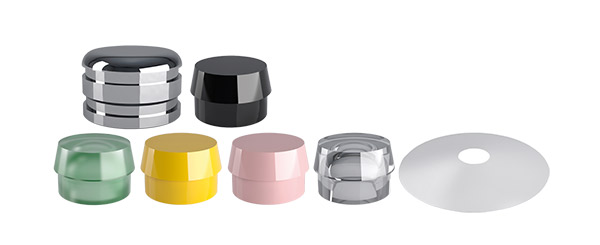

KIT ASSORTIMENTO CAPPETTE OT CAP MICRO

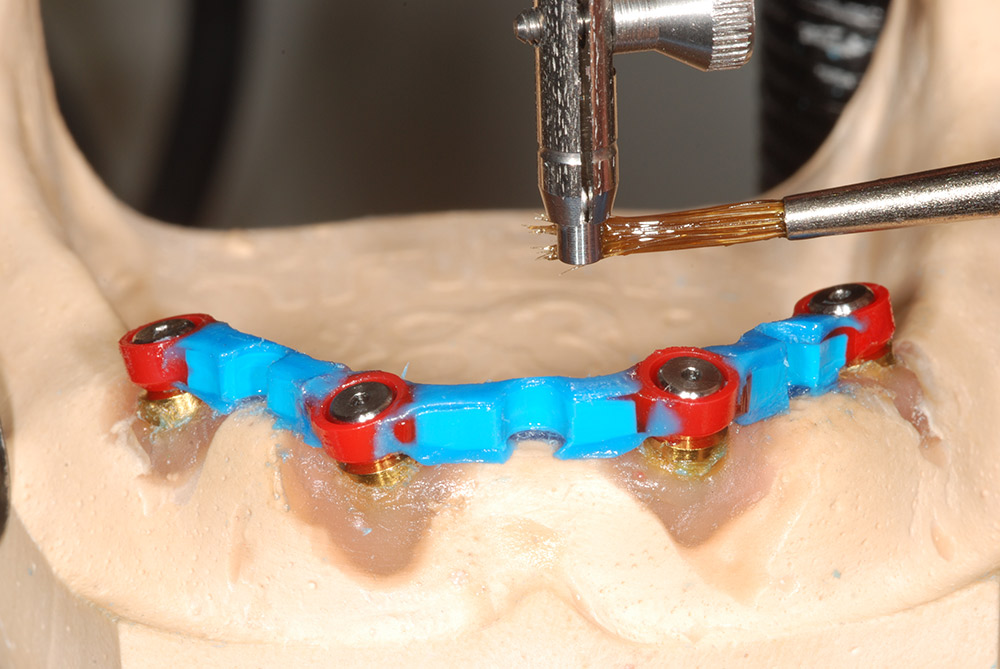

Kit contains:

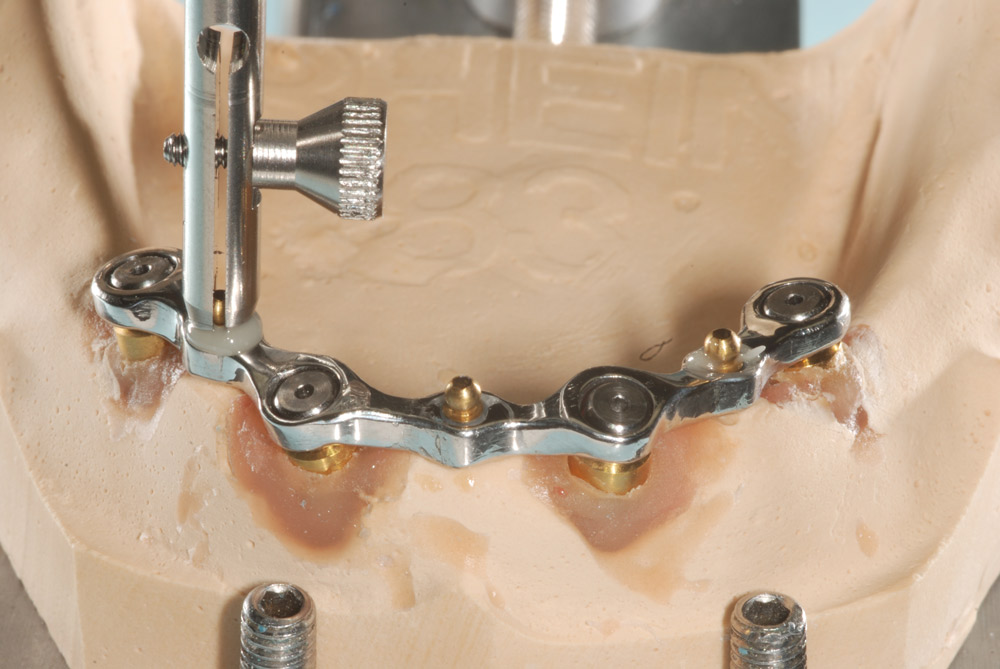

• 1 STAINLESS STEEL HOUSING

• 1 PROCESSING CAP / BLACK (for laboratory)

• 4 RETENTIVE CAPS (1 green, 1 yellow, 1 pink, 1 clear)

• 1 PROTECTIVE DISK

SPARE PARTS

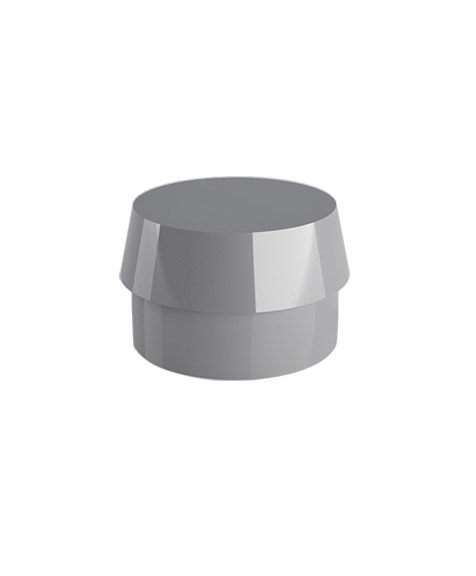

Ref. 048CAM

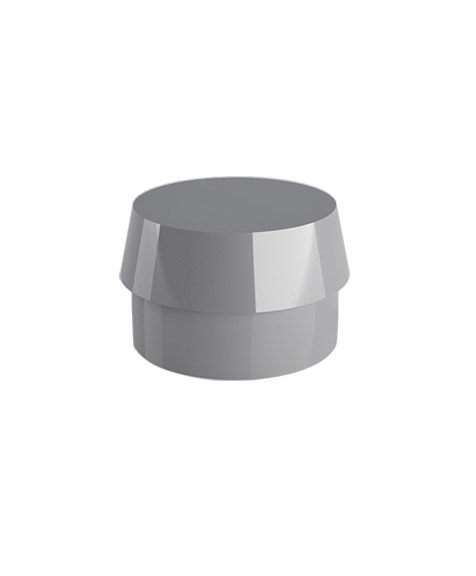

• 6 CAPS EXTRA-RESILIENT MICRO / SILVER (elastic and gummy – 350g)

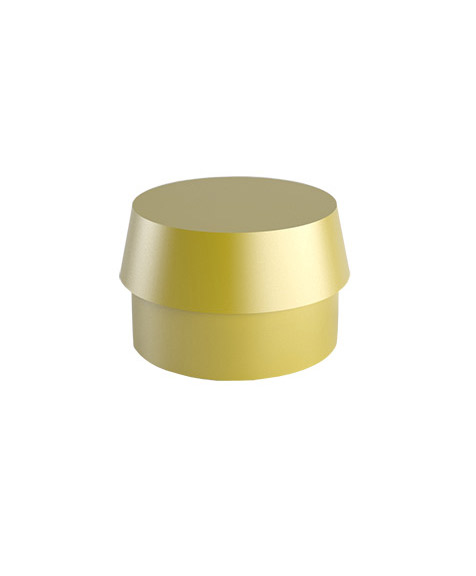

Ref. 048COM

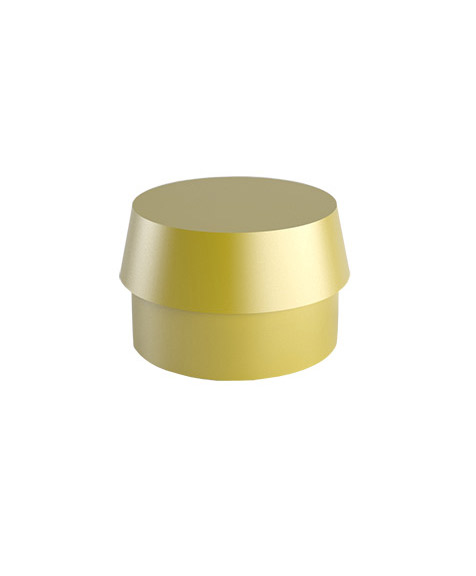

• 6 CAPS EXTRA-RESILIENT / GOLD (slightly elastic – 500g)

Ref. 049PCM

Ref. 049PCM

• 6 CAPS MICRO / GREEN (very elastic retention – 350g)

Ref. 060CRM AY

• CAPS MICRO / YELLOW (extra soft retention - 500g)

Ref. 040CRM SN

• 6 CAPS MICRO / PINK (soft retention – 900g)

Ref. 040CRM

• 6 CAPS MICRO/ CLEAR (soft retention – 900g)

Ref. 040TCM

• 2 TITAN CAPS MICRO

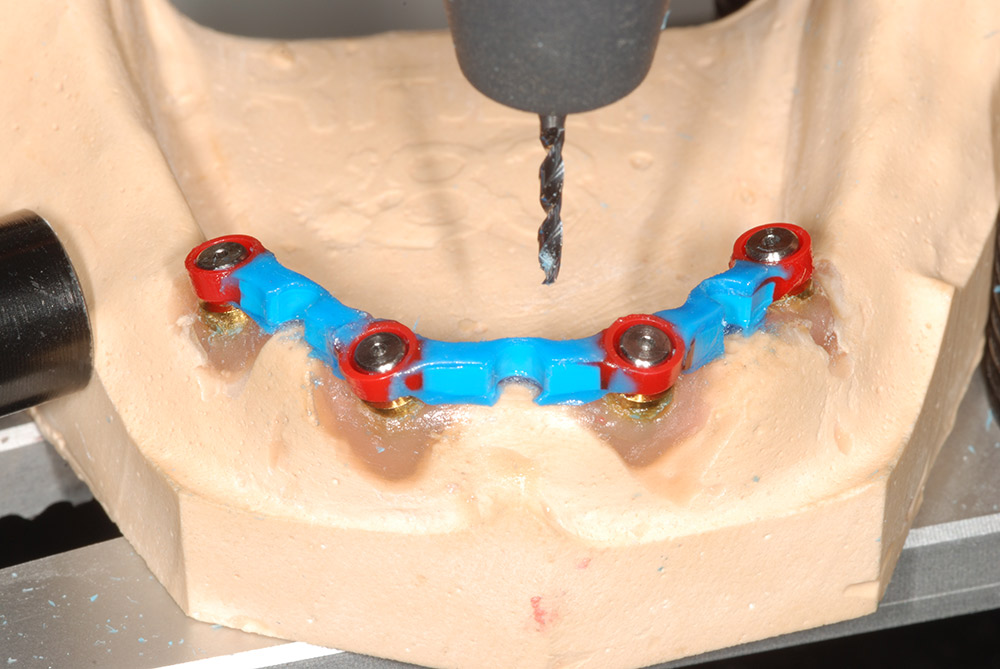

Ref. 043CLM

• 2 CAPS MICRO / BLACK (for laboratory use only)

Ref. 041CAM

• 2 STAINLESS STEEL HOUSINGS MICRO

Ref. 041CTM

• 2 TITANIUM HOUSINGS MICRO

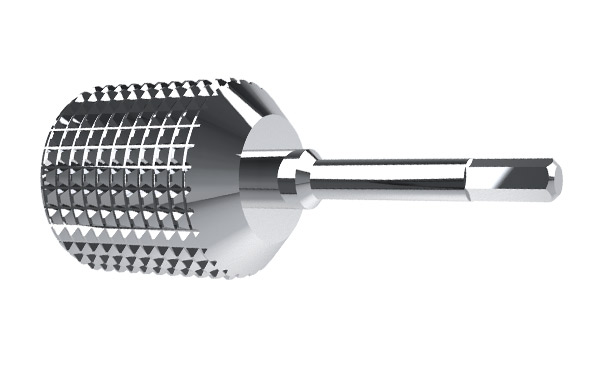

TOOLS

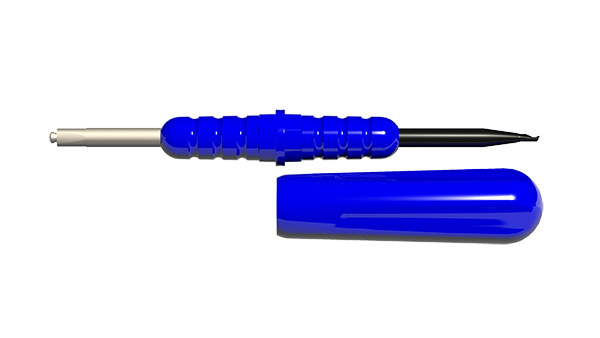

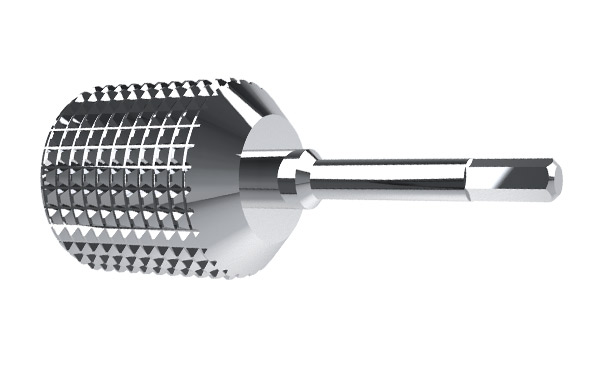

Ref. 772CSF

• 1 HEX DRIVER (for threaded sphere normal hex 1.3mm)

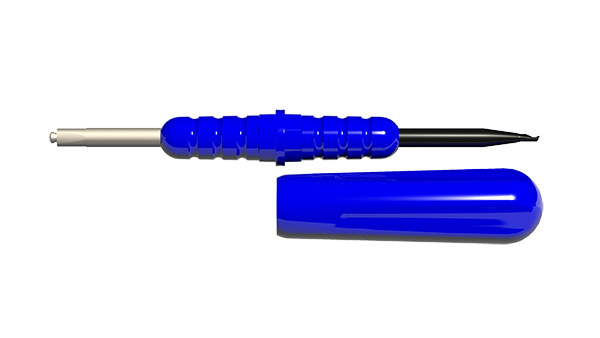

Ref. 485IC

• 1 EXTRACTOR/INSERTER TOOL FOR CAPS (normal and micro sizes - for the insertion of the caps inside the metal housings)