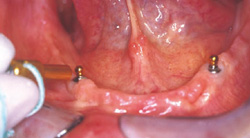

Direct attachment for implants

Sphero Block

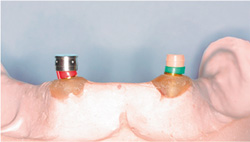

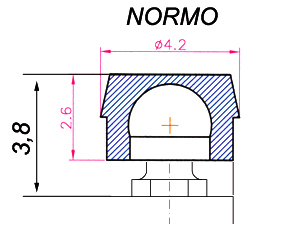

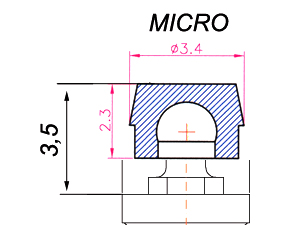

The Sphero Block direct attachment for implants is made of titanium with nitride coating and is available for any implant brand currently on the market in 2.5 mm (Normo) and 1.8 mm (Micro) spherical diameters. The nitride coating is a treatment that gives a surface hardness of 1600 Vickers.

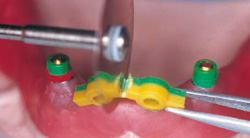

Thanks to the use of directional rings, this attachment corrects disparallelisms of up to 14° for each implant. The functioning of this attachment is guaranteed by the coupling between the sphere and the retention cap inside the metal housing. Retention caps are available in different colours corresponding to the different retention levels.