Sphero Flex

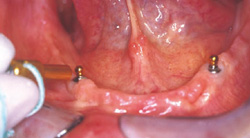

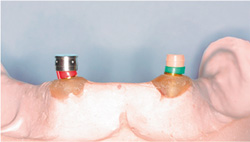

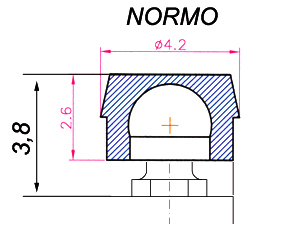

The Sphero Flex implant abutments for overdenture attachments are compatible with any implant system currently on the market. The Sphero Flex swivel ball comes with a diameter of 2.5 mm and is flexible to 7.5 in any direction. Sphero Flex has been designed to correct angulation problems up to 43° between two implant abutments.

This attachment is titanium nitrate coated and has a Vickers surface hardness of 1600. The female component of the attachment is a nylon cap that comes in a variety of colors and snaps over the ball to help prevent wear and increase retention.

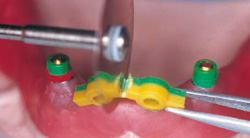

Hex Driver for Torque Controller - Contra Angle

Hex Driver for Torque Controller - Contra Angle Anti-Unscrewing System With Elastic Dowel

Anti-Unscrewing System With Elastic Dowel