PRODUCT INFO

STUDIO

LABORATORY

PRODUCT SPECIFICATIONS

VIDEO

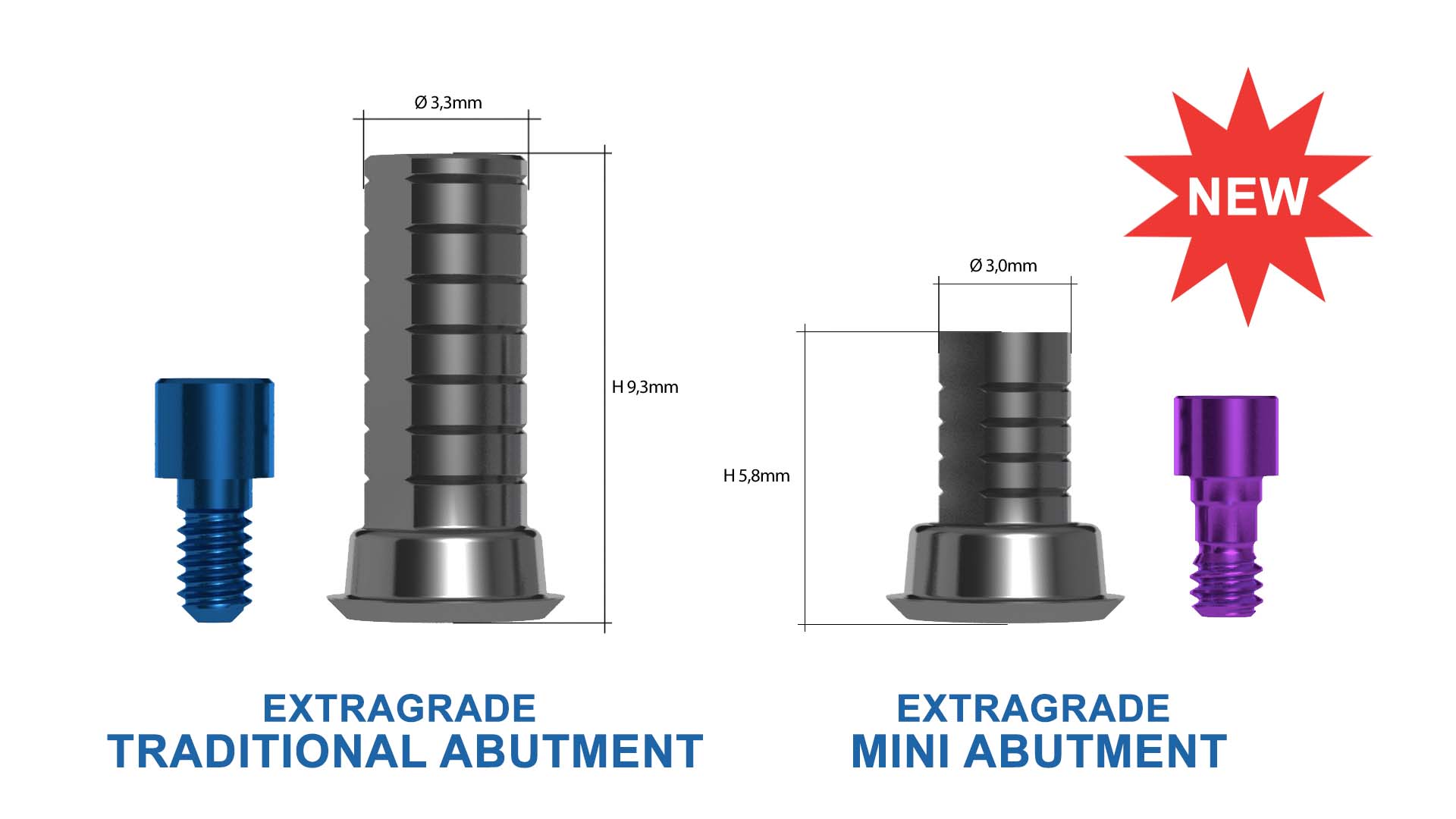

Mini Extragrade titanium T-base with screw and castable sleeve

Mini Extragrade straight T-base with screw and castable sleeve for bonding technique. Available in two diameters.

They are also recommended when the prosthetic screw hole can create aesthetic problems in the fixed denture; thanks to the square purple screw, the screw hole can be inclined by 25 degrees and has areduced diameter compared to the blue square prosthetic screw. In case of particularly inclined implants it is possible to omit one screw (e.g. one out of four in an all-on-four denture), using the undercut of the Ot Equator as a retentive area for the Seeger.

Extragrade titanium T-base with screw and castable sleeve

The Standard Extragrade straight T-base with screw and castable sleeve for bonding technique. Available in three diameters.

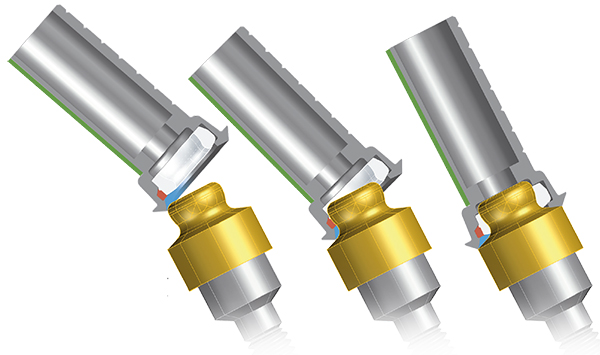

They are recommended when the prosthetic screw hole does not create aesthetic problems in the fixed denture. The yellow square screw is used when the OT Bridge connection is milled directly into the framework even with an inclined hole. In case of particularly inclined implants, it is possible to omit one screw (e.g. one out of four in an all-on-four denture), using the undercut of the Ot Equator as a retentive area for the Seeger.

15° angled Extragrade titanium T-base with screw and castable sleeve

15° angled Extragrade titanium T-base with screw and castable sleeve for bonding technique. Available in two diameters.

They are recommended when the prosthetic screw hole creates aesthetic problems in the fixed denture. Thanks to the round yellow screw, the screw hole can be inclined by 20 degrees. In case of particularly inclined implants, it is possible to omit one screw (e.g. one out of four in an all-on-four denture), using the undercut of the Ot Equator as a retentive area for the Seeger.

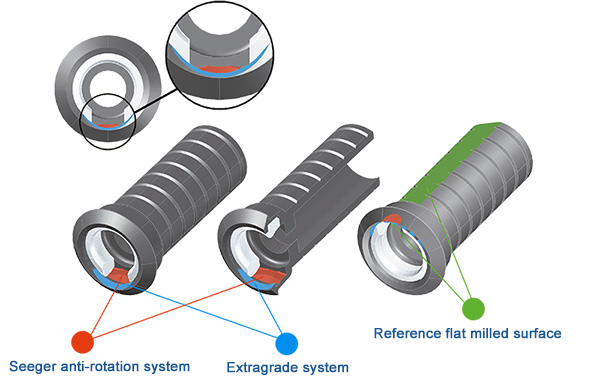

With divergent implants, the extragrade T-base must be inserted with the external flat

milled surface in correspondence of the maximum undercut of the Ot Equator.

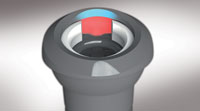

Seeger anti-rotation system

The anti-rotationality of the seeger ring is possible thanks to the stop inside the prosthetic abutment which prevents any seeger rotation.

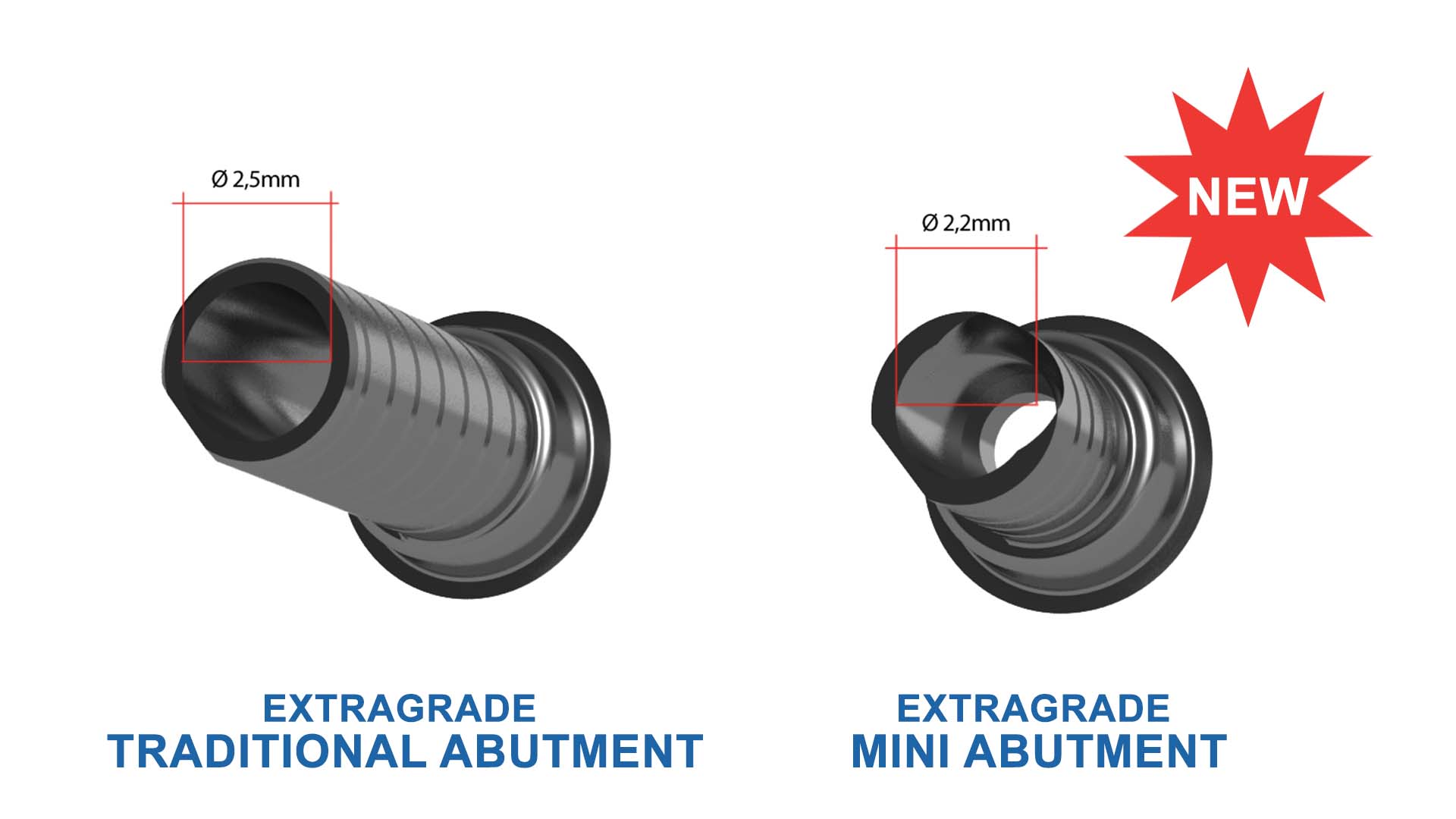

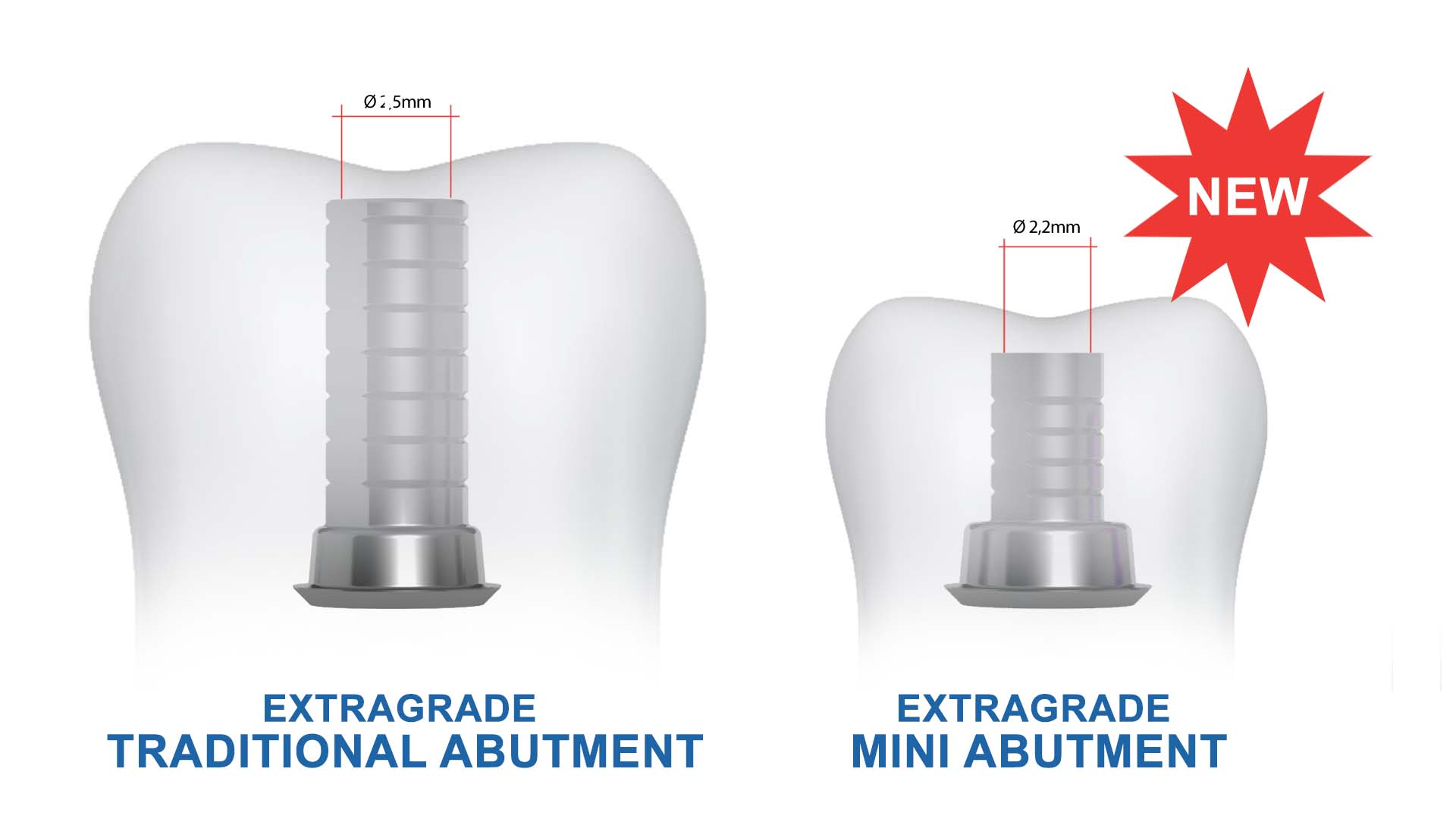

Extragrade system

The OT Bridge prosthetic abutment must be positioned with its extragrade flaring in correspondence of the implant undercut.

Reference flat milled surface

The external flat milled surface acts as reference point and identifies the position of the internal extragrade flaring.

PRODUCT INFO

STUDIO

LABORATORY

PRODUCT SPECIFICATIONS

VIDEO

PRODUCT INFO

MINI EXTRAGRADE TITANIUM T-BASE Ø 3.5 mm

Ref. MMSEG

Kit contains:

• 1 MINI EXTRAGRADE TITANIUM T-BASE TO BE CEMENTED

(h 5.7mm, Ø 3.5mm)

• 1 TITANIUM SCREW FOR MINI EXTRAGRADE TITANIUM ABUTMENT

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

MINI EXTRAGRADE TITANIUM T-BASE Ø 4.0 mm

Ref. MM40SEG

Kit contains:

• 1 MINI EXTRAGRADE TITANIUM T-BASE TO BE CEMENTED

(h 5.7mm, Ø 4,0mm)

• 1 TITANIUM SCREW FOR MINI EXTRAGRADE TITANIUM T-BASE

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM T-BASE Ø 3,5 mm

Ref. MTSEG

Kit contains:

• 1 EXTRAGRADE TITANIUM T-BASE TO BE CEMENTED (h 9.5mm, Ø 3,5mm)

• 1 TITANIUM SCREW (h 2.0mm)

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM T-BASE Ø 4,0 mm

Ref. MT40SEG

Kit contains:

• 1 EXTRAGRADE TITANIUM T-BASE TO BE CEMENTED (h 9.5mm, Ø 4mm)

• 1 TITANIUM SCREW (h 2.0mm)

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM T-BASE Ø 5.0 mm

Ref. MT50SEG

Kit contains:

• 1 EXTRAGRADE TITANIUM T-BASE TO BE CEMENTED (h 9.5mm, Ø 5mm)

• 1 TITANIUM SCREW (h 2.0mm)

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM ABUTMENT T-BASE AT 15°

Ref MTSFEG

Kit contains:

• 1 EXTRAGRADE TITANIUM T-BASE (inclined at 15° to be cemented ø 3,5mm)

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

• 1 TITANIUM SCREW FOR INCLINED T-BASE

EXTRAGRADE TITANIUM T-BASE INCLINED AT 15°

Ref MTEG15SF

Kit contains:

• 1 EXTRAGRADE TITANIUM T-BASE (inclined at 15° to be cemented ø 4mm)

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

• 1 TITANIUM SCREW FOR INCLINED T-BASE

Ref. RMTSFEG

• 1 EXTRAGRADE TITANIUM T-BASE INCLINED AT 15° Ø 3,5mm

Ref. RMTEG15SF

• 1 EXTRAGRADE TITANIUM T-BASE INCLINED AT 15° Ø 4,0mm

Ref. RMMSEG

Ref. RMMSEG

• 1 MINI EXTRAGRADE TITANIUM T-BASE

Ø 3,5mm

Ref. RMM40SEG

Ref. RMM40SEG

• 1 MINI EXTRAGRADE TITANIUM T-BASE

Ø 4,0mm

Ref. RMTSEG

• 1 EXTRAGRADE TITANIUM T-BASE Ø 3,5mm

Ref. RMT40SEG

Ref. RMT40SEG

• 1 EXTRAGRADE TITANIUM T-BASE Ø 4,0mm

Ref. RMT50SEG

• 1 EXTRAGRADE TITANIUM T-BASE Ø 5,0mm

Ref. GMM

Ref. GMM

• 1 CASTABLE SLEEVE FOR MINI TITANIUM EXTRAGRADE T-BASE Ø 3,5mm

Ref. GMM4

Ref. GMM4

• 1 CASTABLE SLEEVE FOR MINI TITANIUM EXTRAGRADE T-BASE Ø 4,0mm

Ref. GCMR

Ref. GCMR

• 1 CASTABLE SLEEVE FOR INCLINED TITANIUM T-BASE WITHOUT HOLE Ø 3,5mm

Ref. GCMR 4

Ref. GCMR 4

• 1 CASTABLE SLEEVE FOR INCLINED TITANIUM T-BASE WITHOUT HOLE Ø 4,0mm

Ref. GC

Ref. GC

• 1 CASTABLE SLEEVE FOR TITANIUM EXTRAGRADE T-BASE Ø 3,5mm

Ref. GC4

Ref. GC4

• 1 CASTABLE SLEEVE FOR TITANIUM EXTRAGRADE T-BASE Ø 4mm

Ref. GC5

Ref. GC5

• 1 CASTABLE SLEEVE FOR TITANIUM EXTRAGRADE T-BASE Ø 5mm

Ref. 030

Ref. 030

• 1 OT EQUATOR TITANIUM ABUTMENT

(with TiN coating)

SCREW AND HEALING RING

Ref. 159VAG

Kit contains:

• 1 HEALING TITANIUM SCREW

• 1 TITANIUM SELF-EXTRACTING HEALING RING

OT EQUATOR SEEGER AND HEALING RING

Ref. 159EAG

Kit contains:

• 1 TITANIUM + TiN OT EQUATOR SEEGER

• 1 TITANIUM SELF-EXTRACTING HEALING RING

Ref. 159VEA

Ref. 159VEA

• 1 OT EQUATOR SEEGER

(for self-extracting peek ring or titanium self-extracting healing ring)

Ref. 145SAE

Ref. 145SAE

• 1 OT EQUATOR TITANIUM SCAN ABUTMENT + TITANIUM SCREW

Ref. 144AE

Ref. 144AE

• 2 LABORATORY ANALOGS ø 4mm

Ref. AI502

Ref. AI502

• 2 LABORATORY ANALOGS ø 5mm

Ref. 144AVC4

Ref. 144AVC4

• 1 LABORATORY ANALOG ø 4mm

(with screw for CAD/CAM)

Ref. 144AVC5

Ref. 144AVC5

• 1 LABORATORY ANALOG ø 5mm

(with screw for CAD/CAM)

Ref. 148VCM

Ref. 148VCM

• 1 TITANIUM SCREW FOR MINI EXTRAGRADE T-BASE

(for screwdriver/stem for inclined Channel)

Ref. 146VMI

• 1 SPHERICAL TITANIUM SCREW FOR INCLINED T-BASE

Ref. 147VME

• 1 TITANIUM SCREW FOR EXTRAGRADE T-BASE

Ref. VC

Ref. VC

• 1 TITANIUM SCREW h 2mm

Ref. VM

Ref. VM

• 1 TITANIUM SCREW h 6mm

Ref. VXL

Ref. VXL

• 1 TITANIUM SCREW h11,5mm

Ref. 022RGO

Ref. 022RGO

• 3 CASTABLE CONNECTION BARS

Ref. SM6

Ref. SM6

• 6 WHITE SEEGERS WITH HANDLE (standard retention)

Ref. SRM6

Ref. SRM6

• 6 PINK SEEGERS WITH HANDLE (soft retention)

Ref. 144TLE

Ref. 144TLE

• 1 TITANIUM LONG IMPRESSION COPING

(+ titanium long screw h 11,5mm)

Ref. 144TTE

Ref. 144TTE

• 1 TITANIUM IMPRESSION COPING

(+ titanium screw h 6mm)

Ref. 144MTE

Ref. 144MTE

• 2 IMPRESSION COPINGS FOR INDIVIDUAL TRAY

Ref. TPM2

Ref. TPM2

•2 MINI IMPRESSION COPINGS h3,7mm

TOOLS

Ref. 774CHE

Ref. 774CHE

• 1 SQUARE SCREW DRIVER + OT EQUATOR HOLDER (square tip 1.25mm usable with the manual torque wrench)

Ref. 775CLE

Ref. 775CLE

• 1 SQUARE LONG SCREW DRIVER + OT EQUATOR HOLDER

(square tip 1.25mm usable with the manual torque wrench)

Ref. 760CS

• 1 LONG SCREWDRIVER/STEM FOR ANGULATED CHANNEL (for torque controller contra-angle square tip 1,25mm)

Ref. 760CSC

• 1 SCREWDRIVER/STEM FOR ANGULATED CHANNEL (for torque controller contra-angle square tip 1,25mm)

Ref. 760ACC

• 1 SCREWDRIVER/STEM FOR ANGULATED CHANNEL ADAPTER (usable with manual torque wrench)

Ref. 760CE

Ref. 760CE

• 1 SQUARE DRIVER CONNECTOR (for torque controller contra-angle square tip 1,25mm)

Ref. 774HC

• 1 INTERCHANGEABLE HOLDER

Ref. 760CRD-US

- 1 MANUAL TORQUE WRENCH FOR OT EQUATOR AND SPHERO BLOCK/FLEX

(Suggested torque: accordingly to the implant brand prescription. Torque wrench range-of-use: 10/70Ncm)

Ref. 124ICP

Ref. 124ICP

• 1 UNIVERSAL HANDLE

COMPOSITE CEMENT OT CEM

Ref. OC

Kit contains:

• 1 BICOMPONENT SYRINGE 5ml

• 10 AUTOMIX TIPS

VIDEO

STUDIO

Scan the scanbody in the mouth. The milled wall of the scan body must face the undercut of the implant.

LABORATORY

DIGITAL SOLUTIONS FOR OT BRIDGE LINE

OPTION A

Scan Abutment scan for Cad design. The milled wall of the scan abutment corresponds to the extragrade part of the titanium T-base and must face the undercut of the implant.

OPTION B

Direct scanning of the titanium T-base for Cad design.

LABORATORY

MANUAL PROCEDURE

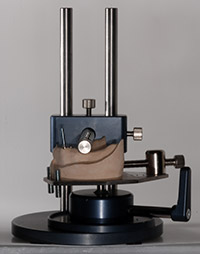

Model analysis using the Rhein83 Parallelometer

Implants divergency analysis.

Analysis of the teeth set-up dimensions. The project is made with the titanium abutments with screws, sleeves to be bonded and titanium T-base inclined at 15° without screws.

Long screw on Ot Equator analog to check where the prosthetic screw hole will be located.

Extragrade Titanium T-base inclined at 15°. The white Seeger must be positioned with its open side towards the Extragrade bevel.

If the screw hole creates aesthetic problems, the titanium T-base pre-angled at 15° with the screw can be used. If the problem persists, it can only be used with the Seeger, but the percentage of abutments without a fixing screw must be limited to 25% (in this case 1 in 4).

It is important to position the titanium T-base with the flat wall on the divergent side, because this corresponds to the chamfer

called the Extragrade, which will allow the girdle to bridge considerable undercuts between the implants.

The Seeger must also have its side open on the divergent side, a position that is forced by an anti-rotational step inside the hole.

The castable sleeve allows the construction of a structure that later will be cast. Then the Extragrade titanium T-base will be passively bonded.

The castable structure must be as passive as possible. Passivity is facilitated by the use of castable gingival connectors that can be

adapted, cut and shaped, trying to leave as little space as possible between these and the implant abutment.

Castable structure ready for casting.

Before bonding, the fitting of the framework should be tested. it is important to cement the elements one at a time. The use of the

Ot Cem composite cement from Rhein83 is recommended.

Place the extra-grade titanium T-base on the OT Equator abutment making sure that the milled wall faces the undercut.

Sprinkle both the outer part of the titanium T-base and the inner surface of the canal to be bonded with cement. Take care to

sprinkle the screw with Vaseline.

Ensure that the milled wall of the extra-grade abutment remains in the correct position.

Work polished, assembled, ready to be covered with the aesthetic material.