EXTRAGRADE TITANIUM ABUTMENT Ø 3,5 mm

Ref. MTSEG

SET CONTENT:

• 1 EXTRAGRADE TITANIUM ABUTMENT TO BE CEMENTED

h9,5mm Ø 3,5mm

• 1 TITANIUM SCREW h2mm

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM ABUTMENT Ø 4,0 mm

Ref. MTSEG

SET CONTENT:

• 1 EXTRAGRADE TITANIUM ABUTMENT TO BE CEMENTED

h9,5mm Ø 4,0mm

• 1 TITANIUM SCREW h2mm

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM ABUTMENT Ø 5,0 mm

Ref. MTSEG

SET CONTENT:

• 1 EXTRAGRADE TITANIUM ABUTMENT FOR CEMENTATION

h9,5mm Ø 5,0mm

• 1 TITANIUM SCREW h2mm

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

Ref MTSFEG

SET CONTENT:

• 1 EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15° TO BE CEMENTED Ø 3,5mm

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

• 1 TITANIUM SCREW FOR INCLINED ABUTMENT

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

Ref MTEG15SF

SET CONTENT:

• 1 EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15° TO BE CEMENTED Ø 4,0 mm

• 2 WHITE SEEGERS WITH HANDLE

• 1 PINK SEEGER WITH HANDLE

• 1 TITANIUM SCREW FOR INCLINED ABUTMENT

Ref. RMTSFEG

• 1 EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15° Ø 3,5mm

Ref. RMTEG15SF

• 1 EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15° Ø 4,0mm

Ref. RMTSEG

• 1 EXTRAGRADE TITANIUM ABUTMENT Ø 3,5mm

Ref. RMT40SEG

Ref. RMT40SEG

• 1 EXTRAGRADE TITANIUM ABUTMENT Ø 4,0mm

Ref. RMT50SEG

• 1 EXTRAGRADE TITANIUM ABUTMENT Ø 5,0mm

Ref. GCMR

Ref. GCMR

• 1 CASTABLE SLEEVE FOR INCLINED TITANIUM ABUTMENT WITHOUT HOLE Ø 3,5mm

Ref. GCMR4

Ref. GCMR4

• 1 CASTABLE SLEEVE FOR INCLINED TITANIUM ABUTMENT WITHOUT HOLE Ø 4,0mm

Ref. GC

Ref. GC

• 1 CASTABLE SLEEVE FOR TITANIUM ABUTMENT Ø 3,5mm

Ref. GC4

Ref. GC4

• 1 CASTABLE SLEEVE FOR TITANIUM ABUTMENT Ø 4mm

Ref. GC5

Ref. GC5

• 1 CASTABLE SLEEVE FOR TITANIUM ABUTMENT Ø 5mm

Ref. 030

Ref. 030

• 1 OT EQUATOR TITANIUM ABUTMENT WITH TiN COATING

Ref. 145SAE

Ref. 145SAE

• 1 OT EQUATOR TITANIUM SCAN ABUTMENT + TITANIUM SCREW

Ref. 146VMI

Ref. 146VMI

• 1 SPHERICAL TITANIUM SCREW FOR INCLINED ABUTMENT

Ref. 147VME

Ref. 147VME

• 1 TITANIUM SCREW FOR EXTRAGRADE ABUTMENT

Ref. VXL

Ref. VXL

• 1 TITANIUM SCREW h11,5mm

Ref. VM

Ref. VM

• 1 TITANIUM SCREW h 6mm

Ref. VC

Ref. VC

• 1 TITANIUM SCREW h 2mm

Ref. 022RGO

Ref. 022RGO

• 3 CASTABLE CONNECTION BARS

Ref. SM6

Ref. SM6

• 6 WHITE SEEGERS WITH HANDLE (standard retention)

Ref. SRM6

Ref. SRM6

• 6 PINK SEEGERS WITH HANDLE (SOFT RETENTION)

Ref. 144MTET

Ref. 144MTET

• 2 IMPRESSION COPINGS FOR INDIVIDUAL TRAY

Ref. TPM2

Ref. TPM2

• 2 MINI IMPRESSION COPINGS h3,7mm

Tools

Ref. 774CHE

Ref. 774CHE

• 1 SQUARE SCREW DRIVER + OT EQUATOR HOLDER

(square tip 1.25mm) (USABLE WITH THE MANUAL TORQUE WRENCH)

Ref. 775CLE

Ref. 775CLE

• 1 SQUARE LONG SCREW DRIVER + OT EQUATOR HOLDER

(square tip 1.25mm) (USABLE WITH THE MANUAL TORQUE WRENCH)

Ref. 760CS

Ref. 760CS

• 1 LONG SCREWDRIVER/STEM FOR ANGULATED CHANNEL

For torque controller contra-angle (square tip 1,25mm)

Ref. 760CSC

Ref. 760CSC

• 1 SCREWDRIVER/STEM FOR ANGULATED CHANNEL

For torque controller contra-angle (square tip 1,25mm)

Ref. 124ICP

Ref. 124ICP

• 1 SCREWDRIVER/STEM FOR ANGULATED CHANNEL ADAPTER

Usable with manual torque wrench

Ref. 774HC

• 1 INTERCHANGEABLE HOLDER

Ref. 760CE

Ref. 760CE

• 1 SQUARE DRIVER CONNECTOR

For torque controller contra-angle (square tip 1,25mm)

Ref. 1760CRD

Ref. 1760CRD

• 1 MANUAL TORQUE WRENCH For Ot Equator and Sphero Block/Flex

(Torque range: 15-35 Ncm - Max. allowed 50Ncm)

Ref. 124ICP

Ref. 124ICP

• 1 UNIVERSAL HANDLE

COMPOSITE CEMENT OT CEM

Ref. 158CCAE

SET CONTENT:

• 1 BICOMPONENT SYRINGE 5ml

• 10 AUTOMATIC PADS

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°  EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

EXTRAGRADE TITANIUM ABUTMENT INCLINED AT 15°

Ref. RMT40SEG

Ref. RMT40SEG

Ref. GCMR

Ref. GCMR Ref. GCMR4

Ref. GCMR4 Ref. GC

Ref. GC Ref. GC4

Ref. GC4 Ref. GC5

Ref. GC5 Ref. 030

Ref. 030 Ref. 145SAE

Ref. 145SAE Ref. 146VMI

Ref. 146VMI Ref. 147VME

Ref. 147VME Ref. VXL

Ref. VXL Ref. VM

Ref. VM Ref. VC

Ref. VC Ref. 022RGO

Ref. 022RGO Ref. SM6

Ref. SM6 Ref. SRM6

Ref. SRM6 Ref. 144MTET

Ref. 144MTET Ref. TPM2

Ref. TPM2 Ref. 774CHE

Ref. 774CHE Ref. 775CLE

Ref. 775CLE Ref. 760CS

Ref. 760CS Ref. 760CSC

Ref. 760CSC Ref. 124ICP

Ref. 124ICP

Ref. 760CE

Ref. 760CE Ref. 1760CRD

Ref. 1760CRD Ref. 124ICP

Ref. 124ICP

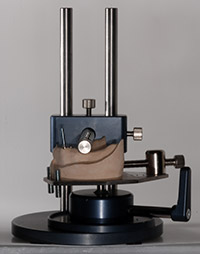

Model analysis with the Rhein83 parallelometer.

Model analysis with the Rhein83 parallelometer. Implants divergency analysis.

Implants divergency analysis. Analysis of the teeth set-up dimensions. The project is made with the titanium abutments with screws, sleeves to be bond- ed and titanium abutments inclined at 15° without screws.

Analysis of the teeth set-up dimensions. The project is made with the titanium abutments with screws, sleeves to be bond- ed and titanium abutments inclined at 15° without screws. Long screw on Ot Equator analog to check where the prosthetic screw hole will be located.

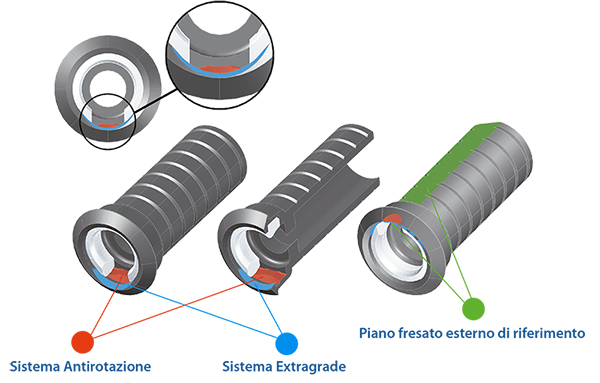

Long screw on Ot Equator analog to check where the prosthetic screw hole will be located. Extragrade Titanium Abutment inclined at 15° without screw. The white Seeger

Extragrade Titanium Abutment inclined at 15° without screw. The white Seeger In case of an excessive implant inclina- tion, it is suggested to use an Extragrade

In case of an excessive implant inclina- tion, it is suggested to use an Extragrade It is important to position the flat surface of the ti- tanium abutment in correspondence with the un- dercut created by the inclination of the implant; the

It is important to position the flat surface of the ti- tanium abutment in correspondence with the un- dercut created by the inclination of the implant; the The open side of the Seeger must be positioned towards the Extragrade, a position that is forced by an anti-rota- tional device located into the abutment.

The open side of the Seeger must be positioned towards the Extragrade, a position that is forced by an anti-rota- tional device located into the abutment. The castable sleeve allows the con- struction of a structure that later will be cast. Then the Extragrade titanium abutments will be passively bonded.

The castable sleeve allows the con- struction of a structure that later will be cast. Then the Extragrade titanium abutments will be passively bonded. The castable structure must be as passive as pos- sible. Passivity is facilitated by the use of castable

The castable structure must be as passive as pos- sible. Passivity is facilitated by the use of castable The castable structure ready to be cast.

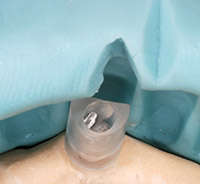

The castable structure ready to be cast. Before bonding, the fitting of the framework should be tested. it is important to cement the ele- ments one at a time. The use of the Ot Cem composite cement from Rhein83 is recommended.

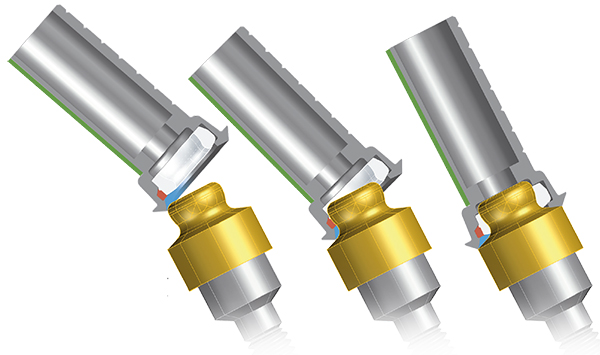

Before bonding, the fitting of the framework should be tested. it is important to cement the ele- ments one at a time. The use of the Ot Cem composite cement from Rhein83 is recommended. Place the Extragrade titani- um abutment with the short screw onto the Ot Equator attachment, making sure to place the flat surface of the titanium abutment in correspondence with the

Place the Extragrade titani- um abutment with the short screw onto the Ot Equator attachment, making sure to place the flat surface of the titanium abutment in correspondence with the The cement should be put on the external part

The cement should be put on the external part Alternatively: screw the tita- nium abutment and smear the

Alternatively: screw the tita- nium abutment and smear the Work polished, assembled, ready to

Work polished, assembled, ready to